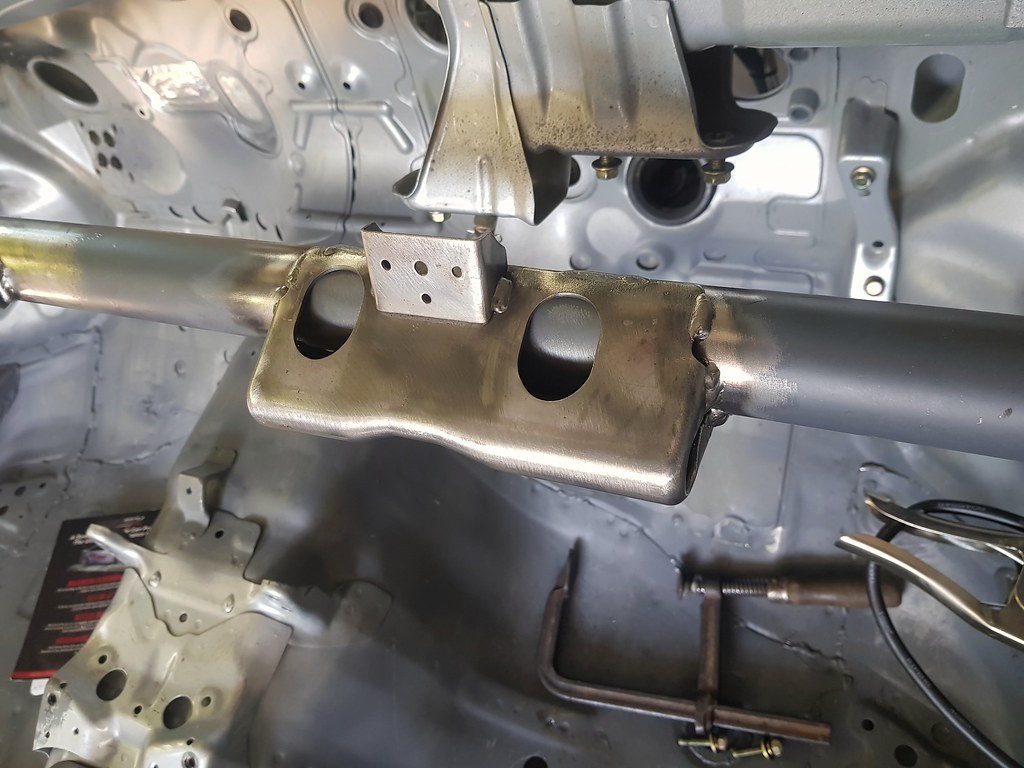

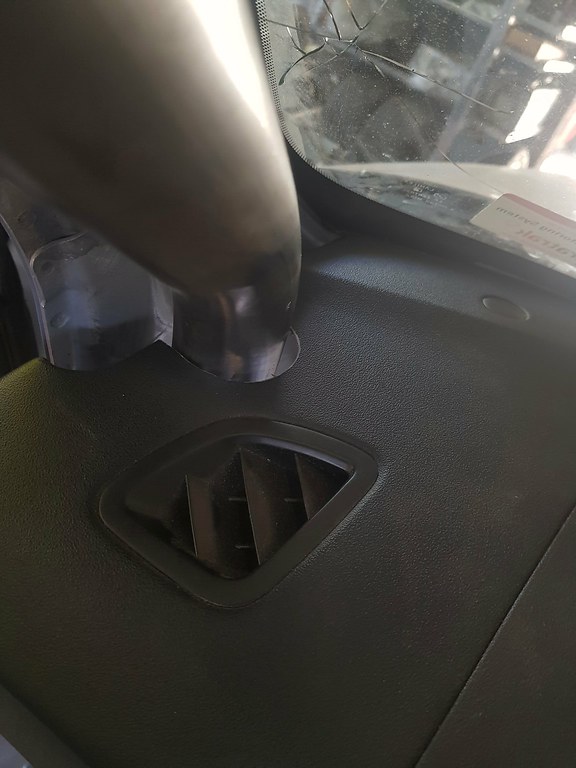

Got the steering column mounting brackets, and dash mounting brackets welded in today. Instead of fabricating new parts, i cheated and chopped the originals out of the OEM dash bar, and trasferred them onto the new dash bar. They line up perfectly with where they need to be. Which means i got the new dash bar welded in at the correct spot. I also gutted the dash, and notched it for the tubes to pass through. So that ready to go back in when the time comes.

2019-01-12_12-21-52

2019-01-12_12-21-52 by

bram biesiekierski, on Flickr

2019-01-12_12-21-59

2019-01-12_12-21-59 by

bram biesiekierski, on Flickr

2019-01-12_07-14-32

2019-01-12_07-14-32 by

bram biesiekierski, on Flickr

I also test fitted my new pedal box. Its a CompBrake twin cylinder unit from the UK. Which replaces the OEM brake pedal mechanism, and mounts the 2 new AP master cylinders inside the cabin area.

https://www.compbrake.com/product/su...ylinder-kit-b/

Im not very happy with it. Its a great idea, but its poorly constructed / implemented by CompBrake. It doesnt fit the car properly, the upper mount doesnt meet the upper mounting point of the firewall. Nothing major, as i can modify it as needed, just need to add some crush tubes and longer bolts, which I happen to have the perfect parts laying about to make it work. But I shouldnt have to.

The master cylinders dont fit the pedal box properly. I have to carefully die grind the radius to allow them to fit neatly. Who ever made it clearly didnt trial fit the cylinders to the frame. Again, nothing major, but I shouldnt have to.

The brake pedal lever fouls the DBW sensor. It needs to be shifted to the left atleast 10mm in order to clear it. This is bloody frustrating. Going to be alot of buggering around to get everything fitted properly. I might have to remake the entire brake pedal lever.

The pedal pad also isnt at the right angle. So im going to have to chop it off, and re-weld it on properly. Thankfully they used bugger all welds to hold it on, so it should be very easy to remove and re-posistion.

And the retards painted inside the tube that houses the balance bar bearing. Which means the balance bar bearing doesnt even fit in the tube. So im going to have to painstakingly sand, clean and polish the inner diameter of the tube so the bearing can slide in side it.

Ontop of that, the tube looks very poorly connected to the brake pedal lever. Because the way the pedal lever pulls against the balance bar tube, it relies on a very small amount of weld to allow the brakes to function. If the tube seperates from the lever, you will lose ALL brakes. So i am going to re-work it so that i am happy with it.

Ontop of that. The frame is lacking welds. I am going to put some extra welds in it as i think who ever built it must have forgot some. Its a box section bracket, made from folded 3mm sheet metal. It should be plenty strong enough, but they havent put in enough welds to hold the different sections of sheetmetal together.

Overall, Im not very happy with the unit. The idea of making a repacement pedal mechanism to house a twin cylinder setup is ingenious, it should basically be a bolt in pedal box. But the actual unit is very poorly built. They could have built it to a much higher standard. But instead have just slapped it together and half-arsed it. Braking is one area of the car that must be done right. And the CompBrake unit doesnt inspire confidence.

2019-01-12_07-14-04

2019-01-12_07-14-04 by

bram biesiekierski, on Flickr

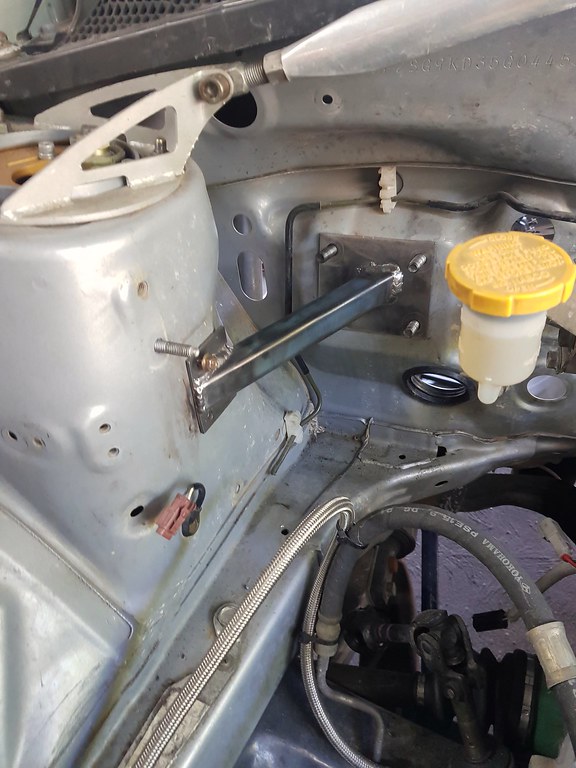

I also built a reinforcment bracket to stiffen the firewall where the brake mechanism connects to. Basically a master cylinder brace to go where the brake booster would have gone. It is a bolt in item so that it can be removed if the need ever arises.

2019-01-12_07-22-02

2019-01-12_07-22-02 by

bram biesiekierski, on Flickr

Master cylinder brace.

Master cylinder brace. by

bram biesiekierski, on Flickr